How to Test Potentiometers in a Welder

There are 2 different types of potentiometers "linear" and "audio". In welders we use linear potentiometers. Other names for potentiometers are pots, variable resistor or rheostat. Most of the time a potentiometer can handle low wattage and has a carbon film strip and rheostat can handle higher wattage and is wire wound but you can check them both the same way.

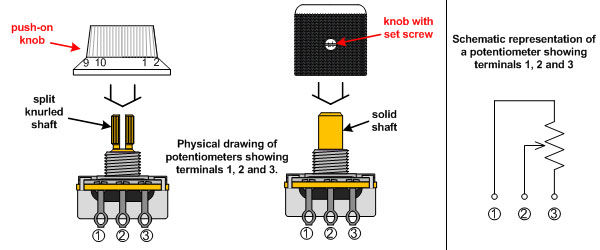

Thay make "special" potentiometers with an "off" switch, dual potentiometers on one shaft, and 10 turn but in this article we are going to talk about normal single turn pot's. In this article I will refer to them as a "pot" or "pots". Below is a picture of a typical pot.

There 2 ways to test a Pot.

1. Out of circuit Test

2. In circuit Test

1. Testing a Potentiometer out of Circuit (No power ohm Test)

Disconnect the pot from the control board or any connections you MUST have at least 2 of the 3 leads disconnected and no power connected to the machine.

All pots have a resistance, common resistances are 1k, 5k, 10k, and 100k (K is 1000 example 5k is 5000 ohm) most of the time on the back of the pot there is a resistance stamped in the pot or you can get it from the spec sheet.

Use the above picture for following tests.

a. Put your meter in ohms (Ω) for this test.

b. Test the resistance from lead (1) to lead (3) it should be within 5% of the pot's rating. This is testing across the resistor.

c. Test the resistance from lead (1) to lead (2). Turn the pot counter clockwise the resistance should decrease all the way to 0Ω. Turn the pot clockwise the resistance will increase from 0Ω to the rated resistance.

d. This test is the opposite from the above. Test the resistance from lead (2) to load (3) clockwise the resistance should decrease all the way to 0Ω. Turn the pot counter clockwise the resistance will increase from 0Ω to the rated resistance.

If it passes the above testing the pot should be working correctly.

2. Testing a Potentimeter In Circuit (With live power)

Warning: Only have qualified personnel check live voltage inside a machine with proper PPE and training.

This test is with the machine on and all wires connected.

Use the above picture for the following tests.

a. Put your meter in Volts DC.

b. Test the voltage from lead (1) to lead (3) this is your supply voltage.

c. Test the voltage from lead (1) to lead (2) this is your wiper voltage. Turn the pot counter clockwise the voltage should decrease all the way to 0 VDC. Turn the pot clockwise the voltage will increase from 0VDC to the supply voltage.